BGB Lubricator

General

The BGB lubricator has a

motor-driven grease pump, making it suitable for medium and large equipment.

According to the choice of grease pump, reversing valve and distributor, the

pump can lubricate above 1,000 lubricating points in a 120M radius. The pump

can be used in single-line or dual-line centralized systems, and also can be

used as a filling grease pump.

Advantages:

1.

Automatic reversing without the necessity to

connect reversing valve.

2.

Low level switch to alarm.

3.

The pump and reservoir can be installed

separately.

4.

Conveniently fill grease at high position.

The pump is widely used in iron and

steel works, rolling mills, cement works and forging machinery.

The pump is firm and convenient to

maintain.

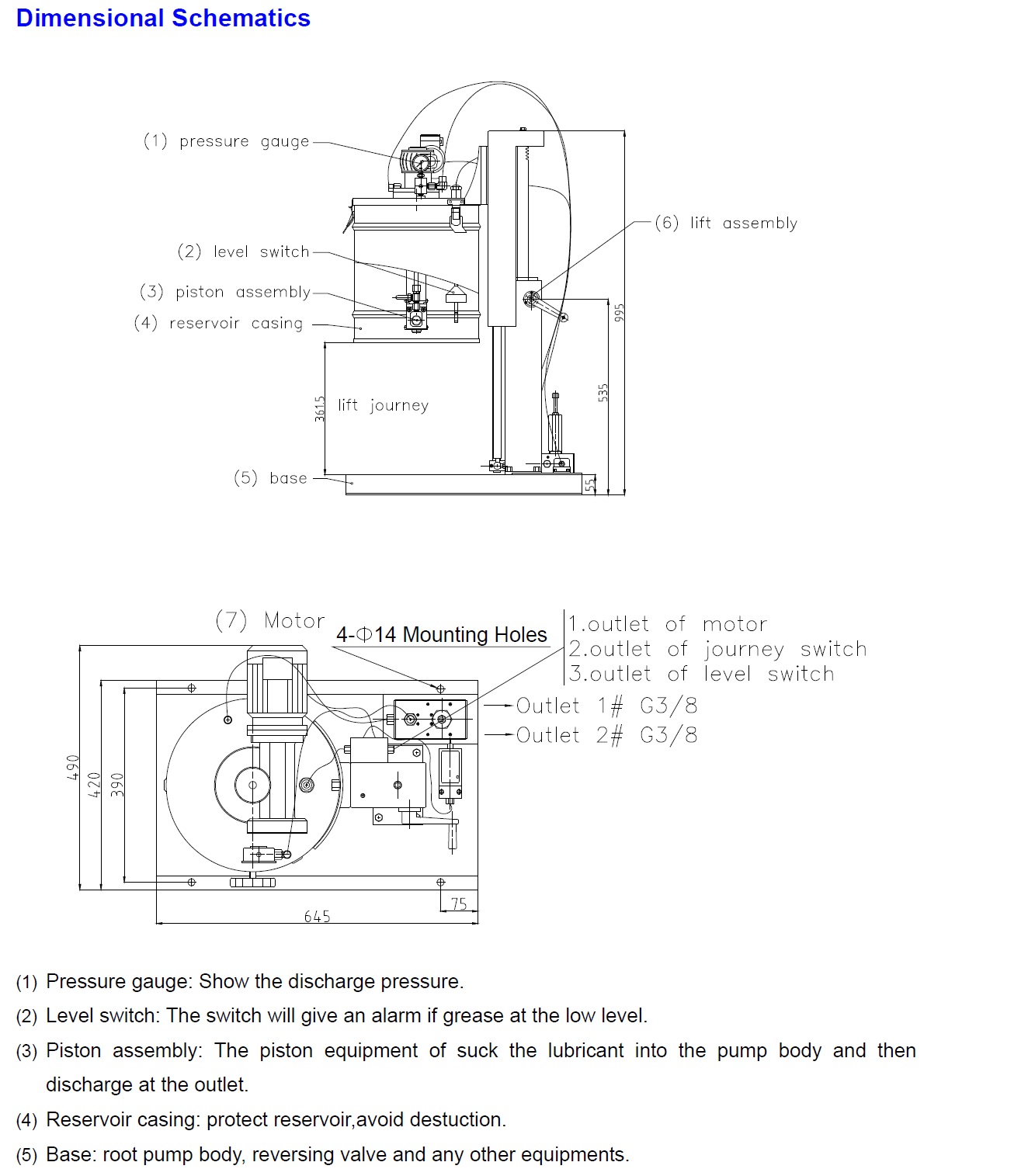

(1)

Pressure gauge: Show the discharge pressure.

(2)

Level switch: the switch will give an alarm if

grease at the low level.

(3)

Piston assembly: the piston equipment of suck

the lubricant into the pump body and then discharge at the outlet.

(4)

Reservoir casing: protect reservoir, avoid

destruction.

(5)

Base: root pump body, reversing valve and any

other equipments.

(6)

Lift assembly: control pump body lift when

change reservoir.

(7)

Motor: Motor drives a eccentric wheel which

drives the piston to move back and forth, the lubricant is sucked into the pump

body and then discharge at the outlet.

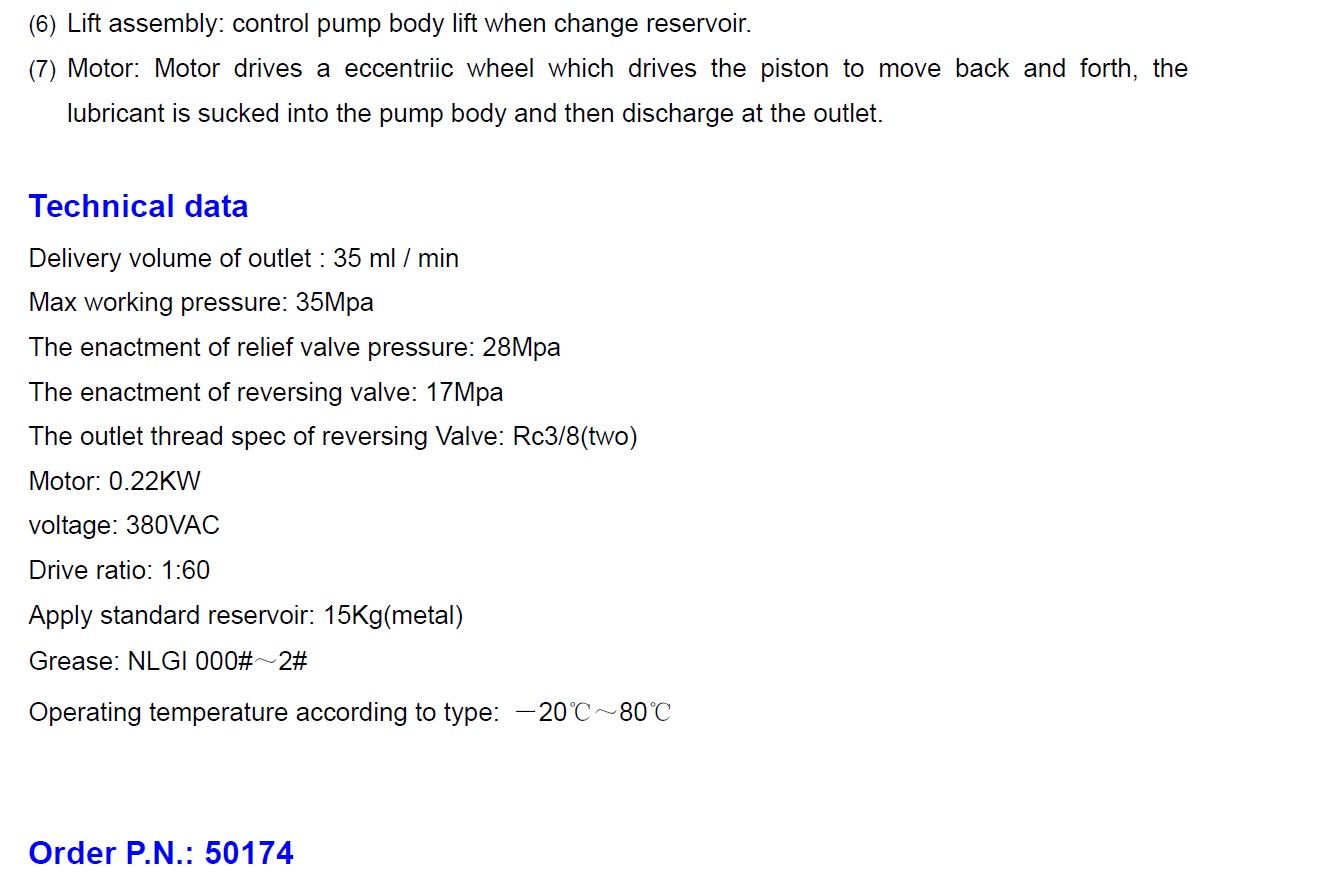

Technical data

Delivery

volume of outlet: 35 mm / min

Max working

pressure: 35Mpa

The enactment

of relief valve pressure: 28Mpa

The enactment

of reversing valve: 17Mpa

The outlet

thread spec of reversing valve: Rc3/8 (two)

Motor: 0.22KW

Voltage:

380VAC

Drive ratio:

1:06

Apply

standard reservoir: 15kg (metal)

Grease: NLGI

000#~2#

Operating

temperature according to type: -200C ~ 800C.