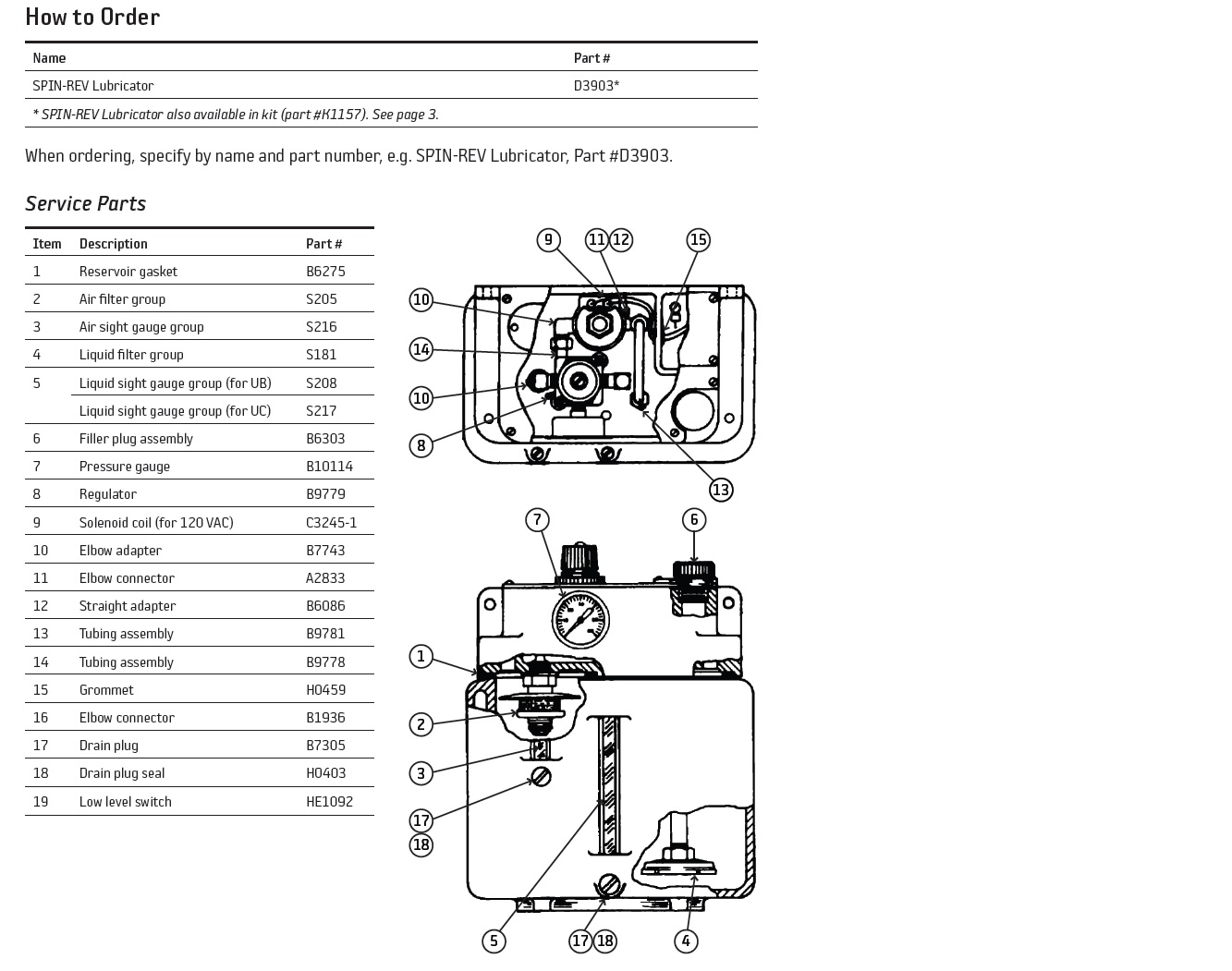

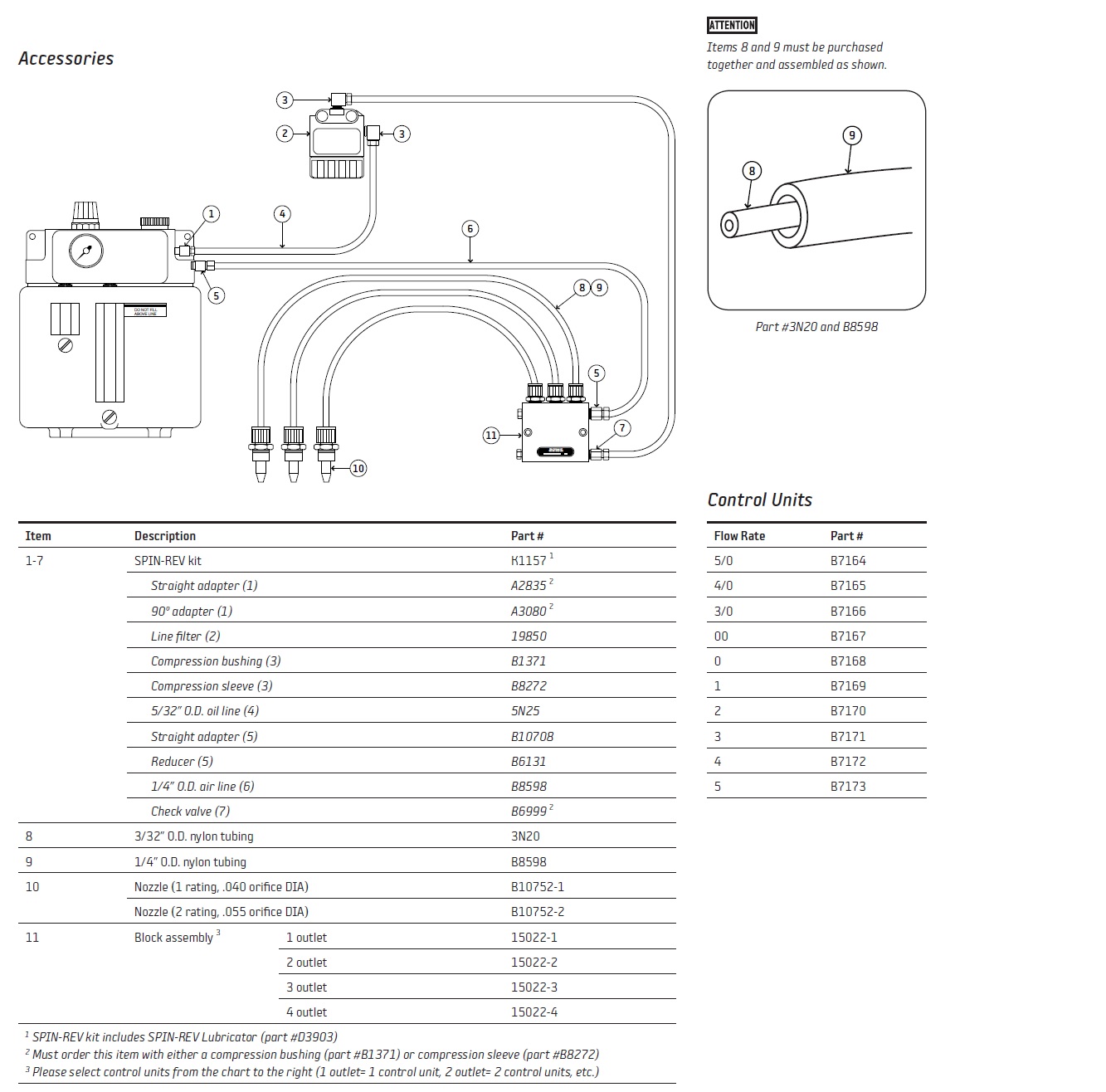

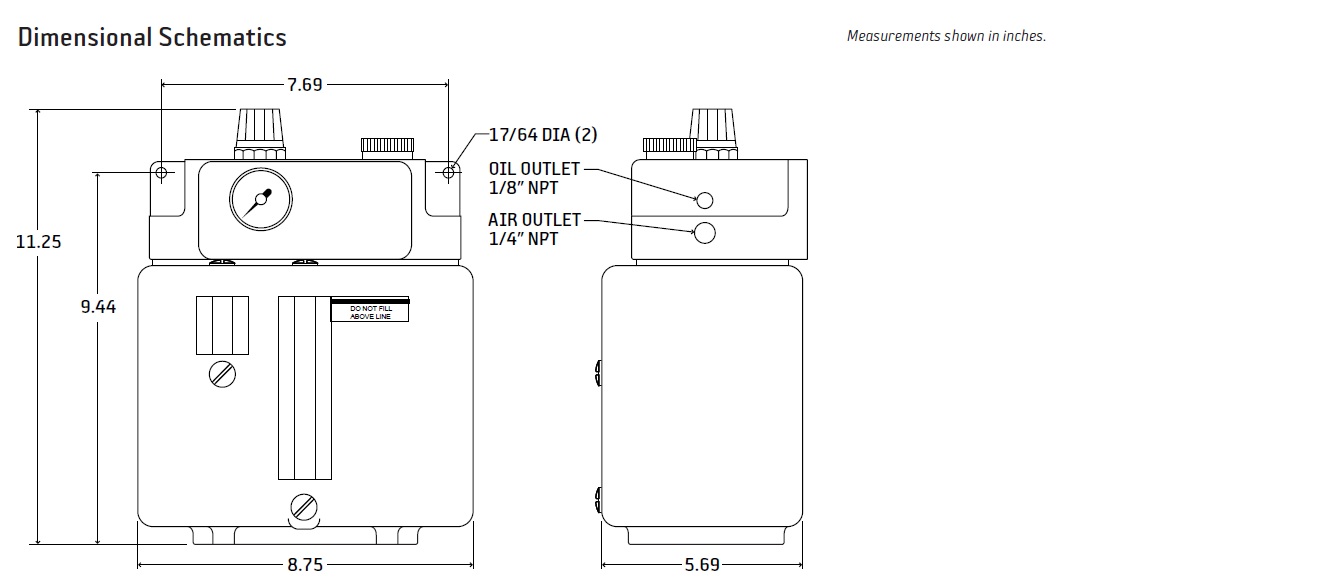

The SPIN-REV Lubricator eliminates residual drift of oil fog or mist during operation. The system utilizes a pressurized oil supply and individual metering devices to carry a wide range of oil viscosities to a variety of high speed, single and multi-spindle applications.

The SPIN-REV Lubricator is capable of delivering very small quantities of lubrication in a continuous mode. Oil is carried through flexible delivery lines to lubrication points (dears, cams, chains, or anti-friction bearings). A separate oil line is contained coaxially within the air-line thus preventing the formation of condensation within the air the lines.

Spray droplets (not mist) are generated at the ends of the distribution line nozzles which eliminate intermittent oil delivery. Optimum lubrication is achieved.

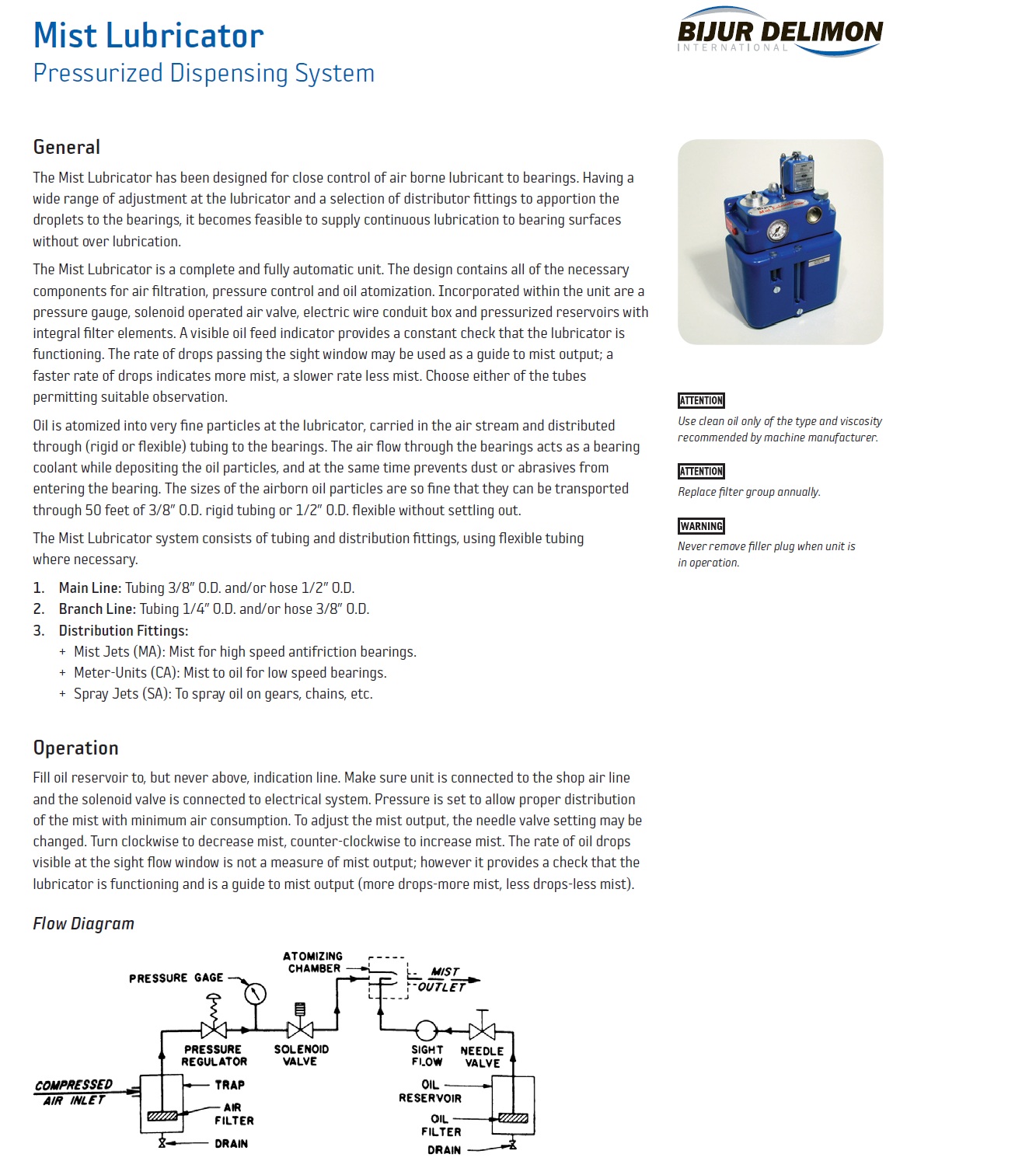

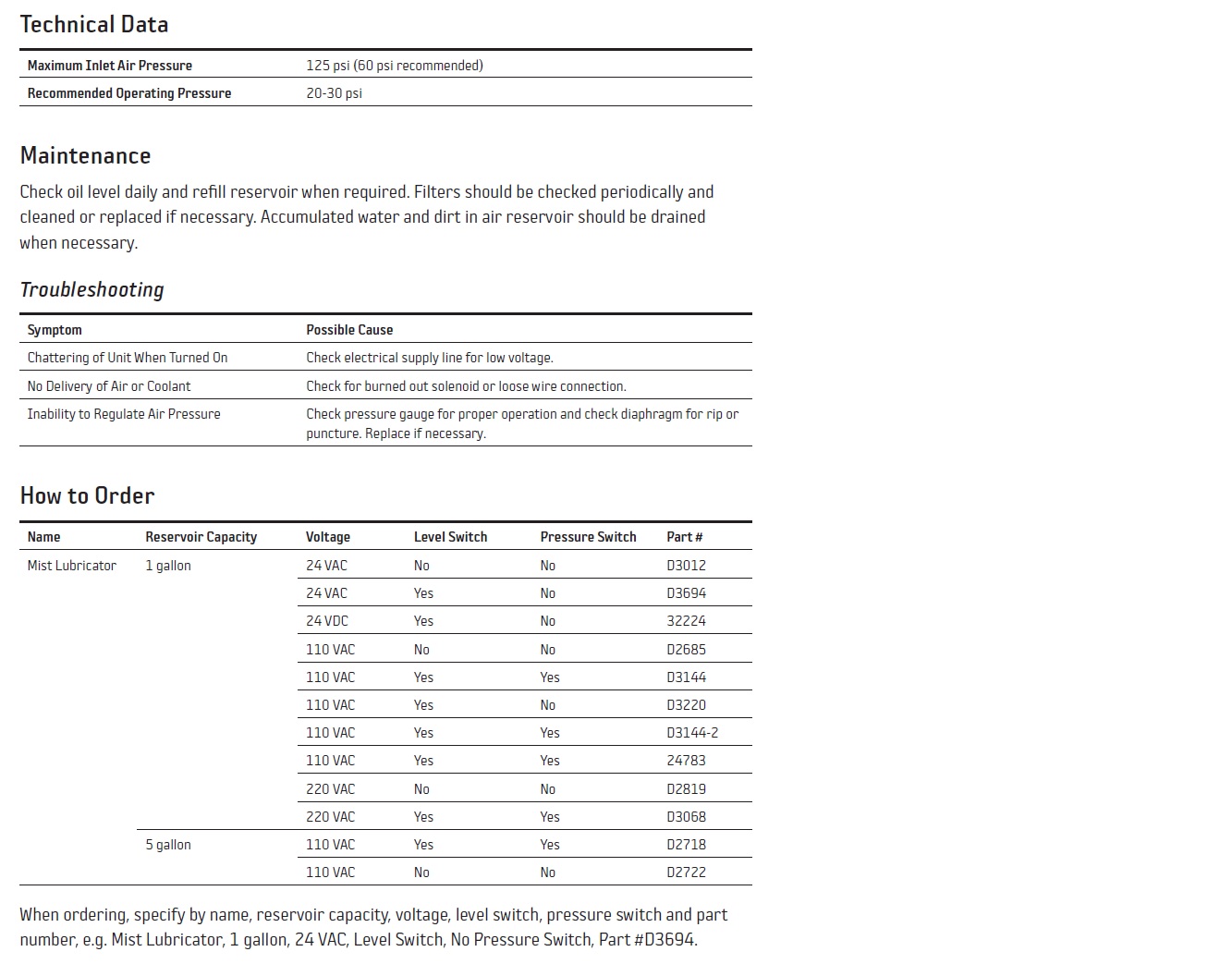

The Mist Lubricator has been designed for close control of air borne lubricant to bearings. Having a wide range of adjustment at the lubricator and a selection of distributor fittings to apportion the droplets to the bearings, it becomes feasible to supply continuous lubrication to bearing surfaces without over lubrication.

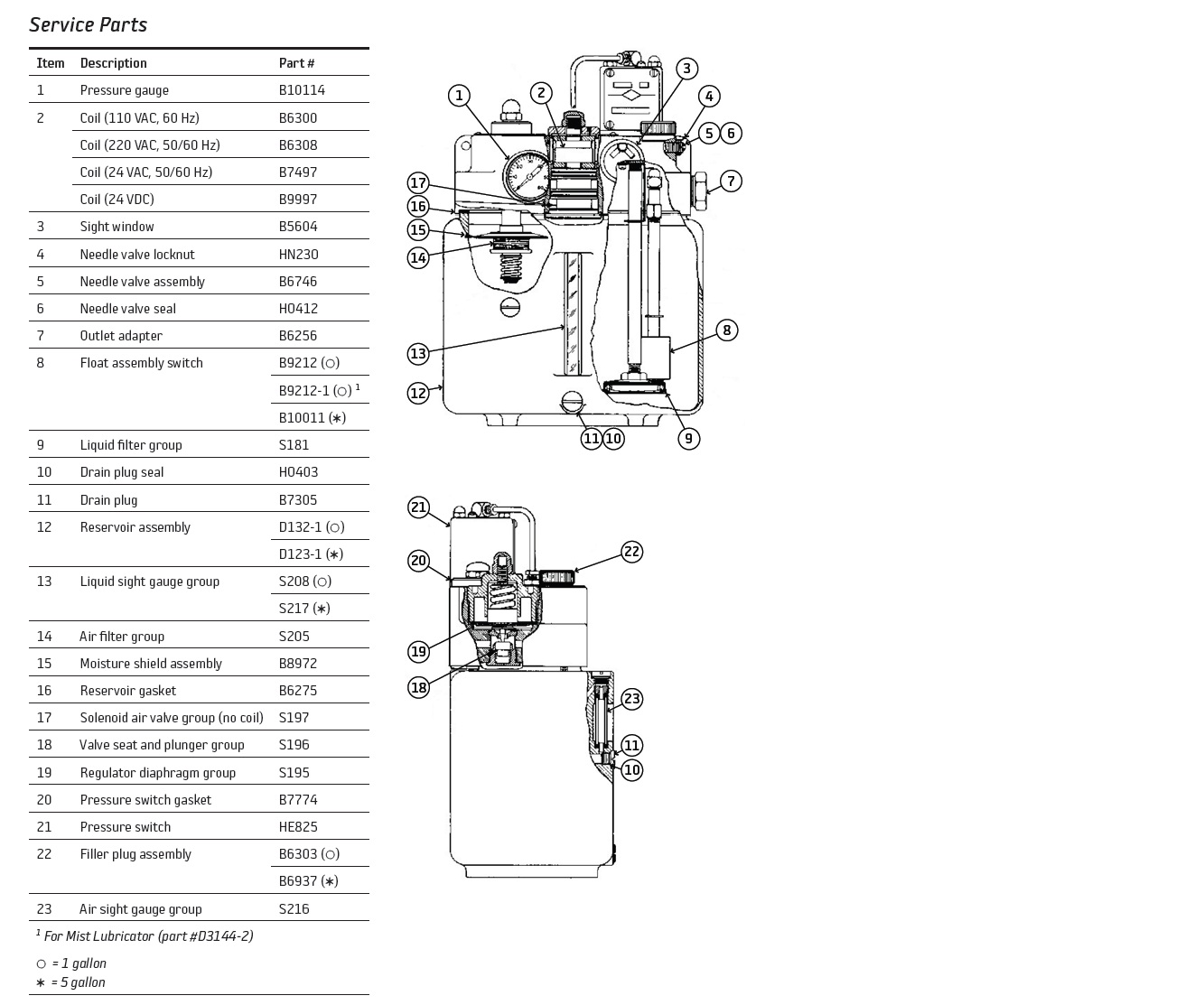

The Mist Lubricator is a complete and fully automatic unit. The design contains all of the necessary components for air filtration, pressure control and oil atomization. Incorporated within the unit are a pressure gauge, solenoid operated air valve, electric wire conduit box and pressurized reservoirs with integral filter elements. A visible oil feed indicator provides a constant check that the lubricator is functioning. The rate of drops passing the sight window may be used as a guide to mist output; a faster rate of drops indicates more mist, a slower rate less mist. Choose either of the tubes permitting suitable observation.